Starch Technology

You are here:

Starch Technology

We offer complete process line for starch manufacturing.

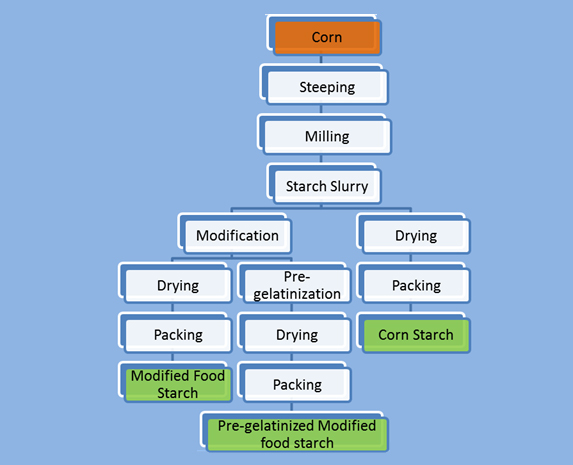

Maize based starch wet milling method:

Brief regarding Wet milling process for starch manufacturing from maize:

Maize is generally processed to manufacture corn starch by wet milling method, throughout the world. Again, by-products obtained during wet milling process like steep liquor, corn oil, Gluten and fiber are important value added products.

Maize grains stored in silos is cleaned and screened for sand, stone and other foreign particles. The cleaned grain is then steeped in water containing Sulphor di-oxide @ 0.2% for around 60 to 70 hours at about 52 0 . By steeping, the grains are softened and the water thus come out of steeping is called steep liquor.

The grains after steeping are subjected to primary and secondary grinding, wherein Germs are separated. De-germed maize is then sent to washing system, where the fibers are taken out by pressure washing. Now, the mixture of Gluten and starch is fed for centrifugal separation and the Gluten is separated from starch. The starch slurry, thus remaining is passed through twelve stage hydro-cyclone washing system, wherein the starch is washed and concentrated.

The concentrated starch is then diverted to various production lines for manufacture of Liquid Glucose and modified starches. The starch is converted in to powder form by passing the wet starch through Dryer.

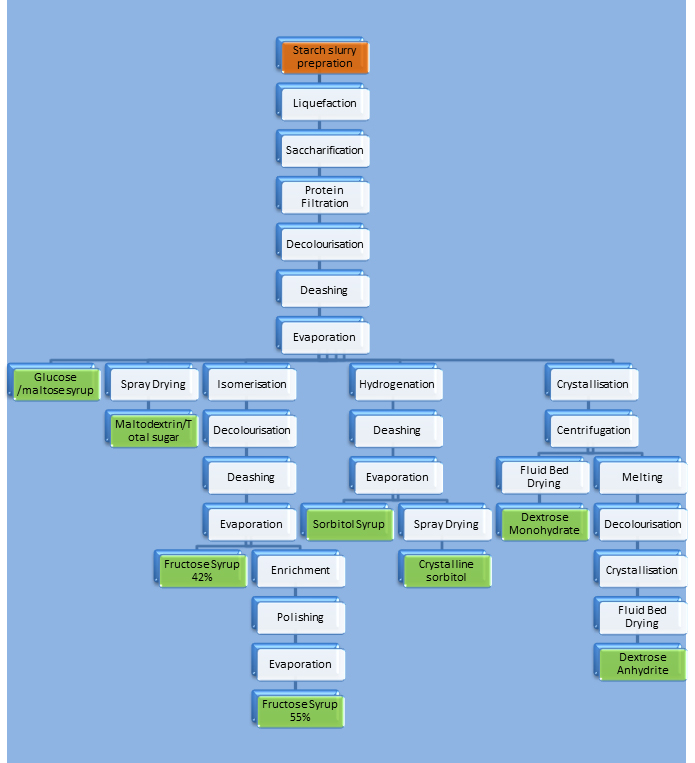

Starch processing implies hydrolysis, i.e. partial or total splitting of the long starch molecules into smaller fragments by chemical or enzymatic processes, purification, concentration and other unit operations for obtaining the required sweetener product.

The processes as well as the equipment are designed with respect to the type of raw material and final product specification.

Sweetener production is performed by a combination of the following key process steps (unit operations).

Liquefaction

The first process step in a sweetener plant is the liquefaction. It comprises a gelatinisation of the starch molecules, facilitating the break-down into smaller molecular fragments. This effect is today mainly obtained by adding enzymes to the starch slurry prior to heat treatment with direct steam injection and by means of reactors to ensure correct reaction conditions.

Saccharification

This is a further enzymatic hydrolysis of the liquefied starch product. The process requires equipment for pH and temperature adjustment and holding tanks for obtaining the required degree of saccharification (i.e. the wanted degree of hydrolysis). Lower degrees of hydrolysis is achieved by inactivation of the enzymes after a certain reaction time.

The saccharified and inactivated product requires refining to remove impurities such as proteins, fibres, fat and soluble components.

Filtration of Insoluble Components

Vacuum Filtration

A rotary vacuum drum filter with a precoat layer of diatomaceous earth or similar filter aid is normally used. Insoluble protein and solid impurities are removed during this filtration.

Membrane Filtration

The system is based on the cross-flow principle. Using ceramic or polymer membranes of very small pore size. It can be used as an alternative to the traditional precoat vacuum filtration. The advantages include the non-necessity of precoat material and a better-refined substrate.

Carbon Treatment

Activated carbon adsorbs colour, proteins and other undesired components from the hydrolysate. The powdered carbon is added to the hydrolysate by a dust tight metering system, and the spent carbon is retained in a vertical candle filter.

The alternative is a granulated carbon treatment system. The hydrolysate passes through a fixed bed column of granulated carbon. After exhaustion, the carbon can be regenerated.

Ion Exchange

After the protein filtration and carbon treatment, further refining is achieved by ion exchange. Cations, anions, amino acids and a number of colouring substances are thereby removed. The system is designed with respect to the product to be produced and involves fixed bed columns filled with cation and anion resins. Single pass, double pass and/or mixed bed solutions can be used. When exhausted, the resin beds are regenerated in-situ with hydrochloric acid and sodium hydroxide. The total operation can be controlled automatically.

Concentration by Evaporation

This raises the solids content of the hydrolysate. Single or multi-effect falling film or plate evaporators are used, applying either thermal or mechanical vapour re-compression.

If the final product is malto-dextrin or glucose syrup solids, the hydrolysate is concentrated to a DS content suitable for spray drying.

If the final product is glucose, maltose or liquid dextrose syrup, refining is followed by evaporation to the desired DS content (Dry Substance, expressed in %). DS in syrups is typically 70-80%.

If the final product is dextrose monohydrate, anhydrous dextrose, fructose syrup or sorbitol the hydrolysate is concentrated to the required DS content for further processing.

Crystallisation

Cooling crystallisation is used for the production of dextrose monohydrate. The crystallizers can be of vertical or horizontal designs, equipped with agitators and cooling facilities.

For anhydrous dextrose an automatically controlled vacuum crystallizer is used as a second crystallisation step.

Isomerization

This is a process for converting glucose into fructose thereby increasing the sweetness of the product. The fixed bed iso-columns containing the immobilised isomerisation enzyme are operated at conditions selected to achieve the specified isomerisation.

Fractionation

To increase the fructose content of the isomerized dextrose syrup a chromatographic separation of fructose and dextrose must be carried out. The solution of dextrose and fructose passes through a column filled with a special resin, separating the solution into a fructose fraction and a dextrose fraction.

Hydrogenation

Sorbitol and other polyols are produced by catalytic hydrogenation of a refined dextrose hydrolysate using special reactors designed for high pressure and temperature operation. The reactors are equipped with heating/cooling facilities, and an effective agitating system.

Fluid Bed Drying

This involves the passing of air through a bed of particles so that a state of fluidization occurs. Fluid bed dryers are selected, being best capable of handling the particulate structure of crystalline sweetener products.

Spray Drying

One of the most important continuous drying techniques for converting liquid sweetener formulations into powders. The feed is atomised into droplets, which are directed into a controlled flow of hot air. Particles are formed as moisture evaporates from each droplet, and the dried product is discharged from the drying chamber.

Depending on type of sweetener various spray dryer designs are selected.

Quick Links

Quick Contact

Phone No. +91 20 2436 2773 / 74

Mr. Satish Yadnik: +91 9822016792

sales@distilleryconsultant.com